Equipment

The production process followes the latest in professional methodology and scientific steps and utilizes the latest technology and the most accurate equipment to get the superior quality with affordable price

Laboratory Analysis

Our onsite certified laboratories conduct all chemical, physical and microbiological tests on all raw materials as soon as they are received from our trusted suppliers. These seriese of tests are designed to detect any microbs, to test quality and insure that our products and raw materials are free of any contaminants.

Defrosting

The drawbacks of conventional defrosting methods can be avoided thanks to the ability of our system to rapidly generate heat volumetrically within the product. The heating process is fast, uniform and controlled, minimizing product deterioration caused by bacterial growth. The heating method we use is the ideal solution for many tempering, softening and defrosting processes. Defrosting is achieved in minutes rather than hours/days, thus helping to preserve at best the product quality

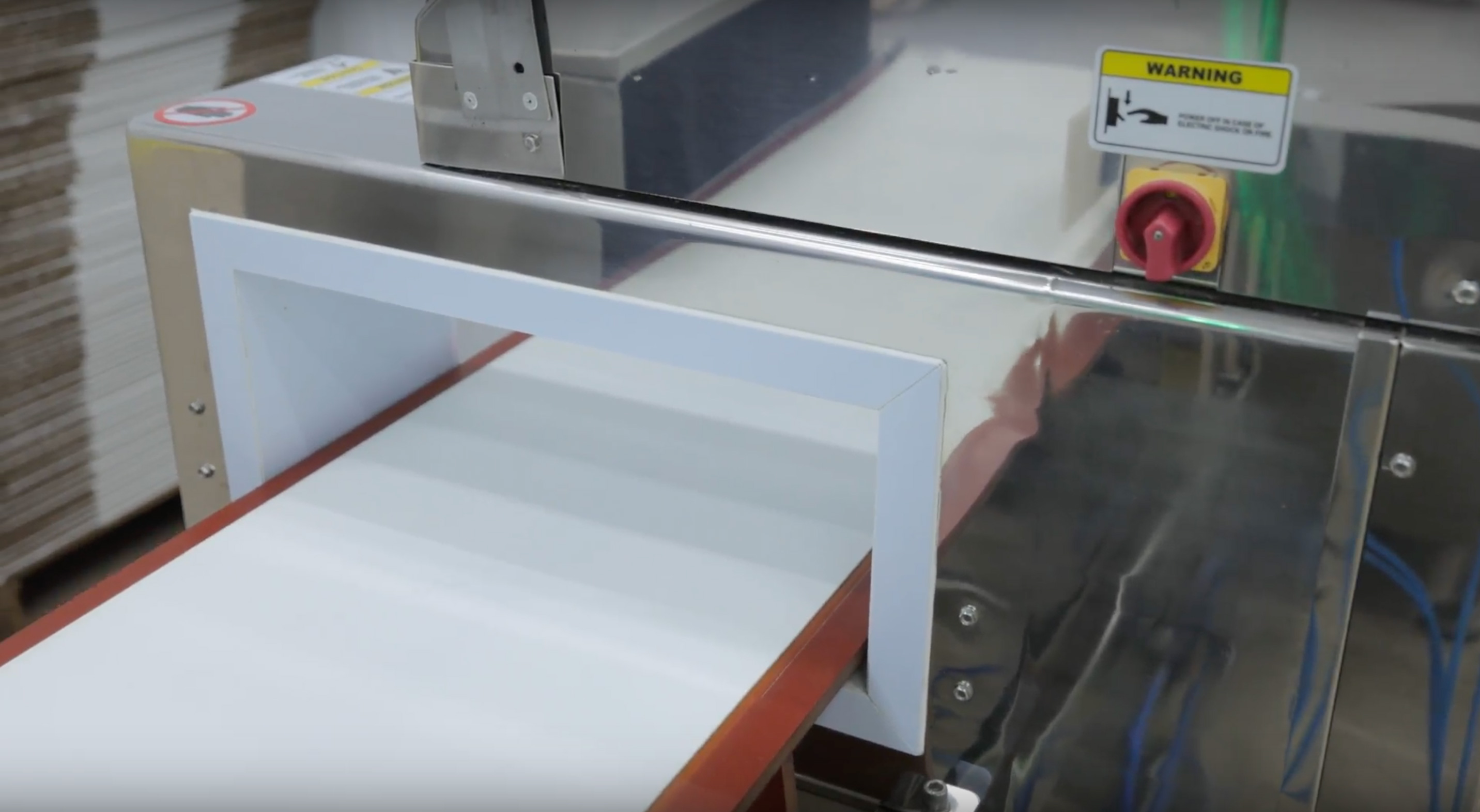

X-ray detection

X-ray technology detects bone and other hard contaminants, such as metal, stone and glass, with unprecedented accuracy and reliability. The system is the most accurate, consistent, and reliable industry standard to detect and reject bone and any other contaminants to increases the quality of the product but also minimizes the risk of recalls and customer complaints.

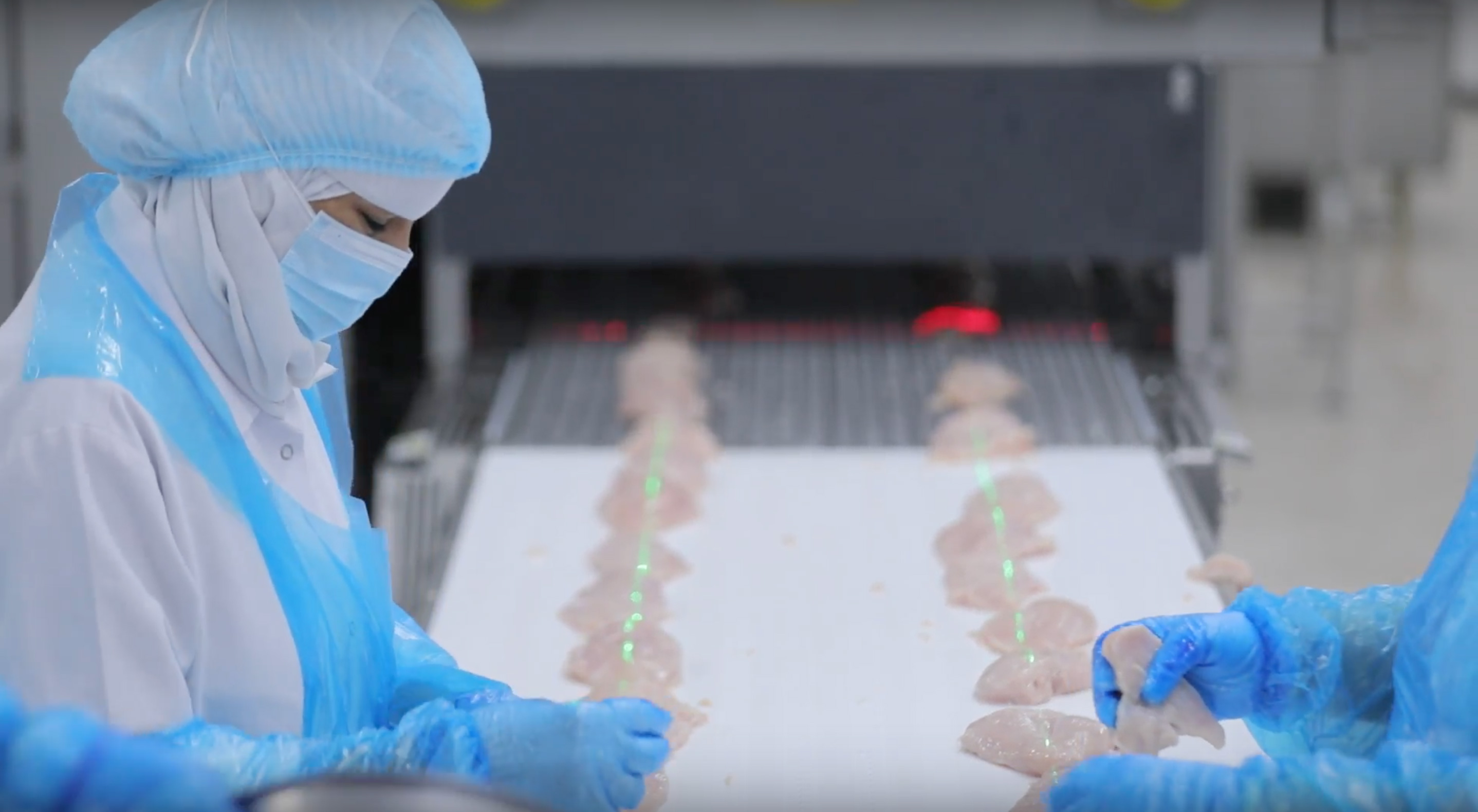

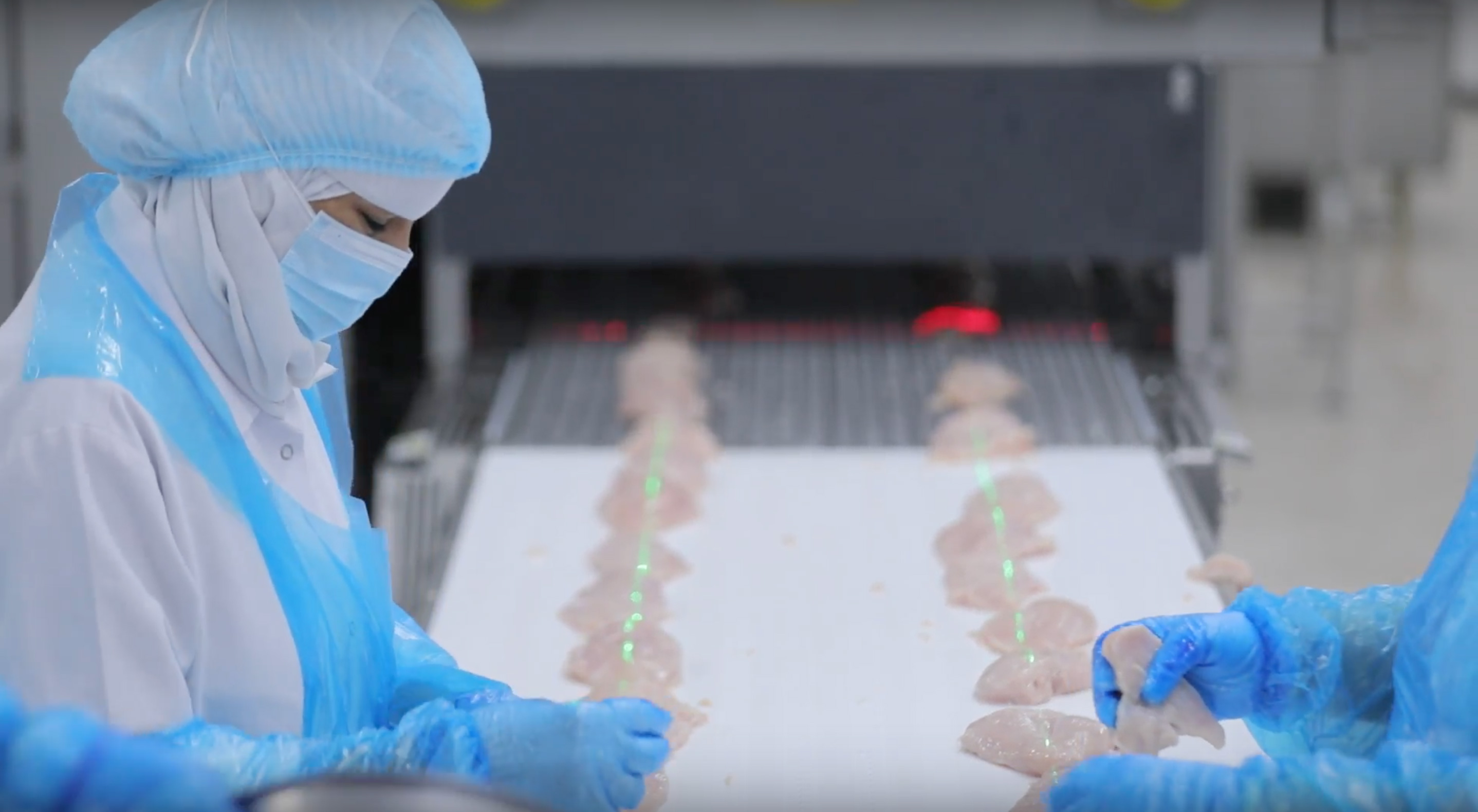

Water-jet Cutting

This equipment scans your the product to locate fat and to determine shape, thickness, weight, and many other attributes then optimizes a cut strategy for each individual piece of raw product then the Computer positions high-pressure waterjets to generate complex cut shapes that make each piece as valuable as possible to minimize waste and delivers consistant quality.

Marination

Tumbler machine improves the microbiological conditions of the products, consolides the natural colour of the protein, and maintains consistent flavour in every piece of product.

Breading and Coating system

It is the ideal solution for poultry products as it provides a process with a high degree of repeatability and control, to be ready for frying with digitally controlled heating and continuous conveyor system. In addition to having the ability to flash fry or fully cook with steam and elevated temperature or steam for different product varieties.

Contact and Spiral Quick Freezing

We have the equipment to produce very high volumes of high quality IQF items with no mesh marks or damages, while maintaining freshness.

Automated weighing and packing

We have the latest in Multi Head weighers and packaging equipment to pack a variaty of small and light to large and heavy products in large volumes.

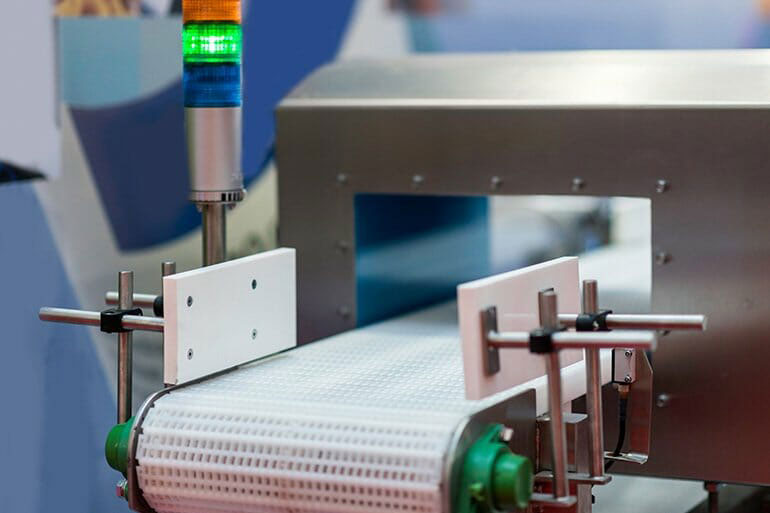

Metal detection

Optimized metal detector mechanics, true Variable Frequency technology, progressive electronics, brings considerable performance in very small metal parts detection.